Spontaneous glass breakage is a phenomenon that can occur in tempered glass, often without any apparent reason. This unexpected shattering can pose safety risks and lead to costly repairs. Understanding what causes this type of breakage and how to prevent it is crucial, especially when dealing with large panels of glass installed in hard-to-access areas.

Understanding Spontaneous Glass Breakage

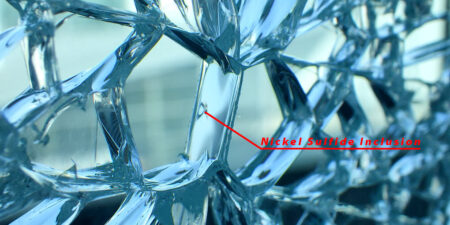

Spontaneous glass breakage is the sudden and unexpected shattering of tempered glass. The primary cause of this breakage is the expansion of nickel sulfide inclusions, tiny impurities within the glass that can expand under heat. This expansion creates internal stresses that, over time, can cause the glass to shatter suddenly.

What is Tempered Glass?

Tempered glass, also known as toughened glass, is glass that has been processed by controlled thermal treatments to increase its strength compared with normal glass. The tempering process makes the glass much harder to break and ensures that if it does break, it shatters into small, blunt pieces that are less likely to cause injury. All glass from Glass Flooring Systems is tempered.

The Role of Heat Soaking

Heat soaking is a process designed to reduce the risk of glass breakage in tempered glass. The process involves heating the glass in a special oven at a specific temperature to induce any nickel sulfide inclusions to expand and cause the glass to break in a controlled environment. This step aims to eliminate any panels that might later fail from nickel sulfide inclusions after installation. At Glass Flooring Systems, we use heat soaking on our products to prevent breakage.

Why Heat Soaking Is Essential for Safety

In locations where replacing a broken glass panel is difficult or where glass failure could pose significant safety risks, a heat soak is particularly important. By ensuring that glass panels are heat-soaked, manufacturers and installers can significantly reduce the likelihood of an unexpected breakage, thus safeguarding both the structural integrity of the building and the safety of its occupants.

Choosing the Right Glass for Your Needs

When selecting glass for any application, especially where large panels are involved, it’s important to consider whether the glass has undergone the heat soaking process. Opting for heat-soaked a tempered glass window can be particularly crucial in applications like skylights, balconies, or other architectural features where spontaneous breakage could have severe consequences.

Spontaneous glass breakage can be a troubling issue, but understanding its causes and taking preventive measures can help mitigate risks. Heat soaking, along with choosing the right type of tempered glass, plays a critical role in ensuring the safety and durability of glass installations. By being informed about the potential issues and solutions, you can make better decisions to protect your property and ensure the longevity of your glass installations.

.png)