Integrating a glass floor into your architectural projects not only enhances aesthetic appeal but also introduces functionality that traditional flooring can’t match. However, working with glass flooring often raises questions about safety, maintenance, and customization. Learn the most common FAQs about glass floors to help you navigate the complexities of these innovative systems.

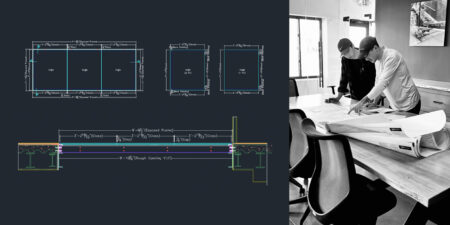

Are Your Products Manufactured In-House?

All our glass flooring products are manufactured in-house, which allows for stringent quality control and customization. Whether it’s a fully assembled unit ready for installation or a knocked-down kit for assembly on-site, each piece is crafted to exact specifications detailed in approved shop drawings. This in-house manufacturing ensures each installation is perfectly tailored to meet project-specific requirements.

Do You Offer Engineering and Drafting for Walkable Glass Floors?

Absolutely, we provide comprehensive drafting services and additional engineering for each glass floor project. After you approve the proposal, we generate detailed shop drawings that outline all critical aspects of your glass floor installation, including frame type, color, glass specifications, and dimensions. For projects with unique requirements, we collaborate with engineering experts to ensure that every installation is not only aesthetically pleasing but also structurally sound.

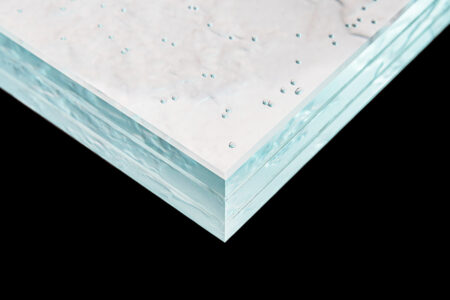

What Is Triple Laminated Glass and Does GFS Offer It?

Triple laminated glass, which is our standard for all glass floor products, consists of three layers of glass bonded with layers of polyvinyl butyral (PVB) or SentryGlas interlayers. This type of glass is incredibly durable and safe, making it ideal for high-traffic areas and overhead applications. It offers enhanced safety, sound reduction, and UV protection, ensuring that your glass floor is both functional and secure. Our top layer consists

of safe, non-slip surfaces that pass the ANSI A326.3 American National Standard Test Method for measuring Dynamic Coefficient of Friction on walkable glass.

What Is Low Iron Glass and Does GFS Offer It?

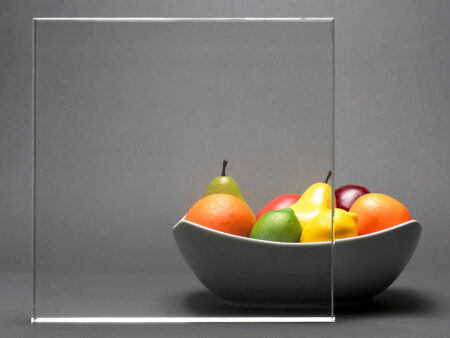

Yes, we standardly include Low Iron Glass in all our glass products at no additional cost. Low iron glass is known for its high clarity and minimal tint, which makes it perfect for applications where clear visibility and true color representation are crucial. This ultra-clear glass ensures that the aesthetic qualities of your glass floor are uncompromised, enhancing the natural beauty of your space.

Are Your Anti-Slip Textures Properly Tested?

We’re proud to use the most trusted anti-slip glass floor top layers available, bar none. These anti-slip layers are meticulously crafted and thoroughly tested to surpass maximum safety requirements for pedestrian traffic.

Working with a glass floor in an architectural project offers a range of benefits and brings a modern edge to any space. By addressing these FAQs, we aim to provide clarity and confidence for anyone considering glass floors for their next project. Glass Flooring Systems is committed to delivering high-quality, reliable, and stunning glass flooring solutions that meet the needs of the most demanding projects. Whether you are creating a feature in a private residence or a focal point in a public space, our glass floors promise to deliver safety, beauty, and durability.

.png)