Our SkyFloor® Series 2000 walkable skylight is now ICC Certified. – Click here for more information

The Ultimate Guide to Walkable Skylights

Everything You Need to Know About a Walkable Glass Skylight

A glass skylight can transform a dark interior, a tired terrace, or an underused roof into a bright, functional extension of your space. When engineered as a walkable skylight, it becomes both a light source and a durable surface people can safely use. This guide explains how modern skylights are built, tested, and installed, and how to plan for structure, drainage, thermal performance, anti-slip safety, and code compliance. Whether you are an architect, contractor, designer, or homeowner, you will find clear steps for evaluating options and integrating a skylight window into your next project with confidence.

Table of Contents

- What Is a Walkable Glass Skylight?

- Benefits: Light, Space, and Experience

- Ideal Applications for Roof Skylights

- Structural Engineering Fundamentals

- Glazing Makeup and Interlayers

- Framing Systems and Finishes

- Thermal Performance and Energy Ratings

- Waterproofing, Drainage, and Roof Integration

- Anti-Slip Safety and Surface Options

- Privacy, Shading, and Glare Control

- Maintenance, Cleaning, and Longevity

- Cost Drivers and ROI

- Common Considerations in Walkable Skylight Projects

- Sustainability and Daylighting Strategy

- Related Articles and Resources

What Is a Walkable Glass Skylight

A walkable glass skylight is a structural glazing system installed on a roof, terrace, or deck that provides both daylighting and a safe, usable surface. Unlike traditional roof skylights designed only for light transmission, a walkable unit is engineered to carry live loads, resist impacts, and maintain traction in varied weather.

The unit typically combines laminated, tempered glass, structural interlayers, and a thermally broken, weatherproof frame. The result is a clean plane that transmits natural light to interiors while supporting foot traffic above, unlocking new square footage and visual drama for homes and commercial buildings.

Benefits:

Light, Space, and Experience

Walkable skylights create a powerful sensory experience. They deliver top-down daylight that reduces reliance on artificial lighting, improves circadian comfort, and highlights finishes with crisp, directional illumination. Functionally, they enable rooftop circulation, seating, and outdoor rooms while keeping interiors bright below.

A walkable glass skylight can solve dark-basement problems, connect multilevel spaces, and create memorable views to sky or canopy. Design teams value the minimal, modern aesthetic and the ability to align glass planes across floors, landings, and terraces. Owners value usable space, increased real estate appeal, and a signature focal point that sets a property apart.

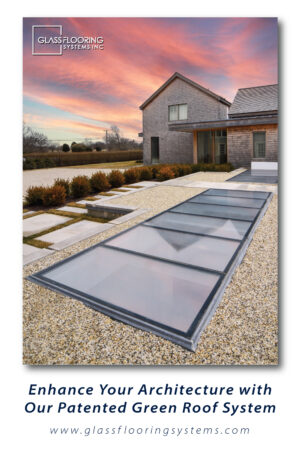

Ideal Applications for Roof Skylights

Walkable roof skylights work wherever daylight and outdoor utility matter. Residential projects use them in rooftop patios, over kitchens, in hall galleries, and above basements to send light deep into the plan. Commercial and cultural projects use them for terraces, hospitality decks, entry courts, and museum circulation where views and natural light shape the guest experience.

They also excel over below-grade spaces, bringing clarity and openness to garages, fitness rooms, or work areas. When combined with glass floors, bridges, or stairs, a walkable unit becomes the anchor of a cohesive, light-forward architecture.

Structural Engineering Fundamentals

Performance starts with structure. A walkable unit must be engineered for live load, deflection limits, impact, and concentrated loads at edges and corners. Laminated, tempered lites work in concert with high-strength interlayers to create passive redundancy. Frames distribute loads to support construction and manage thermal movement.

Engineering submittals typically include finite element analysis where applicable, shop drawings, and state-specific calculations. Coordination with the roof’s framing, blocking, and substrate is essential to carry point loads and to ensure level, plumb placement. Proper engineering ensures the glass skylight functions like a safe floor while maintaining optical clarity and long-term stability.

Glazing Makeup and Interlayers

Glazing stacks vary by project. Typical walkable makeups use triple or quad laminates of low-iron tempered glass for clarity, strength, and impact resistance. Structural interlayers, such as ionoplast, add stiffness and post-breakage integrity. The top lite often carries a tested anti-slip surface that preserves transparency or introduces controlled diffusion.

For energy performance, insulated glass units with low-E coatings and gas fills reduce heat transfer while maintaining visible light transmission. Perimeter ceramic frit or back-painting masks seals and creates a crisp edge. The final specification balances load capacity, optical goals, energy targets, and safety under real-world use.

Framing Systems and Finishes

Frames for walkable units are typically thermally broken aluminum or custom structural steel, selected for span, layout, and project conditions. Thermally broken aluminum frames offer excellent energy performance, integrated gutters, and clean profiles. Steel frames support long spans, heavy loads, and large single-light configurations while allowing tailored details.

Finish options range from high-performance architectural coatings to custom colors that match railings or roof assemblies. Proper frame design simplifies installation by aligning setting gaskets, sealant joints, and fastener paths, and by integrating drains and weeps that protect the assembly over time.

Thermal Performance and Energy Ratings

Energy efficiency is a core benefit of modern skylights. Low-E coatings, gas-filled cavities, warm-edge spacers, and thermally broken frames work together to minimize heat loss in winter and heat gain in summer. The result is a comfortable interior with controlled solar transmission and reduced HVAC demand.

Performance can be documented through third-party ratings so design teams can model daylight, glare, and energy in tandem. Specifying the right glazing package ensures the skylight window improves comfort and helps projects meet sustainability targets without sacrificing clarity, views, or structural capacity.

Waterproofing, Drainage, and Roof Integration

Water management is essential for durability. Quality walkable frames integrate primary and secondary seals, internal gutters, and positive-drain weeps that route water away from insulated glass edges and structure. On the roof, the assembly must tie into membranes and flashing systems per manufacturer details, with special attention at corners and terminations.

Sloped substrates promote drainage and minimize ponding. For terraces with pavers, the skylight can recess to align with walking surfaces and include edge protection. Proper integration protects both the skylight and the building envelope while preserving the clean, minimal look owners expect.

Anti-Slip Safety and Surface Options

Walkable top surfaces must be safe in wet and dry conditions. Tested anti-slip textures range from transparent micro-patterns that preserve views to satin or frosted treatments that add privacy and diffusion. Options like our proprietary NanoDot® and Seeded Organic® textures create high traction without compromising clarity, while our YorLux® and Tahoe satin textures provide the ideal level of privacy with reliable traction.

At Glass Flooring Systems, we offer the industry’s largest selection of tested anti-slip surfaces and are committed to setting the standard for excellence. That’s why our anti-slip walkable glass textures are rigorously tested using the ANSI A326.3 method for both wet and dry conditions.

Privacy, Shading, and Glare Control

Top-down light can be tuned for comfort and privacy. Frosted interlayers, screen-printed patterns, or satin textures reduce visibility into sensitive areas and soften glare. Exterior shading from planters, trellises, or pergolas controls solar gain and adds a landscape layer to the composition.

Interior shades can supplement the system where needed, although many owners prefer fixed optical solutions that keep the surface simple. Aligning texture, tint, and shading early in design ensures the walkable skylight supports daily comfort across seasons without compromising the clean geometry that makes it a signature feature.

Maintenance, Cleaning, and Longevity

Maintaining walkable skylights is simple:

Walkable skylights do not require any additional maintenance like any other flooring, but a little care goes a long way in keeping them safe, bright, and beautiful for years to come.

- Clean glass panels with a non-abrasive glass cleaner or mild soap and water to remove dirt, pollen, and debris. Avoid harsh or abrasive chemicals.

- Use protective pads under furniture or other objects you place on the glass and avoid dragging heavy items across the surface of the glass.

Please keep in mind although you can walk on these skylights, it is still glass and should be treated as such.

Cost Drivers and ROI

Budgets for walkable units reflect structural loads, size, framing type, glazing complexity, thermal targets, and installation logistics. Larger single-light panels and long spans require more robust frames and thicker laminates. Thermally broken frames and high-performance IGUs add efficiency that lowers operating costs over time.

Projects often realize value through added usable area, improved leasing or resale potential, and distinctive branding. Planning early with realistic spans and coordination can reduce change orders and accelerate approvals, improving total project economics for skylights on new builds and renovations.

Common Considerations in Walkable Skylight Projects

Projects run into trouble when structure, drainage, or slip resistance are addressed late. Undersized supports can lead to deflection problems. Missing slope or clogged weeps can trap water and stress seals. Selecting the wrong top surface can create glare or traction concerns.

Avoid these issues by engaging engineering early, selecting a tested anti-slip texture, coordinating waterproofing details with the roofer, and protecting the unit during construction. A quality glass skylight is the result of design, testing, and disciplined installation, not a field-built afterthought.

Sustainability and Daylighting Strategy

A well-placed walkable skylight supports sustainable design. Daylighting reduces lighting loads and can enhance occupant well-being. Thermal breaks, low-E coatings, and gas fills elevate performance, while durable materials support long life cycles. Integrate the skylight with green roofs, planter beds, or paver systems to manage stormwater and heat island effects.

Model daylight and glare to position the unit where it contributes most, then pair with interior finishes that bounce light deeper into the plan. The result is a resilient solution that aligns aesthetics with measurable energy and comfort outcomes.

When planned and installed correctly, a glass skylight can elevate architecture, add usable rooftop space, and flood interiors with beautiful daylight. By aligning structure, glazing, framing, energy performance, waterproofing, and anti-slip safety, design teams can create a walkable skylight that performs day after day while looking refined from every angle.

Whether you’re brightening a basement, activating a terrace, or shaping a new hospitality deck, the right approach to roof skylights will unlock lasting value for people, projects, and places.

The Ultimate Guide to Glass Staircase Design and Installation

Ultimate Guide to Glass Staircase Design and Installation

A glass staircase transforms more than your floor plan: it elevates your entire space. Whether you’re planning a modern residential remodel or designing a high-end commercial interior, this guide provides everything you need to know about glass staircases. From structural safety to visual impact, we’ll walk you through every aspect of planning, building, and installing a staircase that reflects today’s boldest design standards.

Table of Contents

- What Is a Glass Staircase?

- The Benefits of Using Glass for Stairs

- Floating Glass Staircases: Style Meets Engineering

- Key Applications for Glass Stairs

- Design Considerations for Modern Staircases

- Glass Stairwell Safety and Code Compliance

- Structural Support and Framing Options

- Anti-Slip Textures for Glass Staircases

- Customization Options: Shapes, Edges, and Finishes

- Our Process

- Common Considerations in Glass Staircase Projects

- Glass Staircase Trends and Inspiration

- Integrating Glass Staircases with Other Glass Elements

- Glass Staircases in Multi-Use and Public Spaces

- Related Articles and Resources

What Is a Glass Staircase?

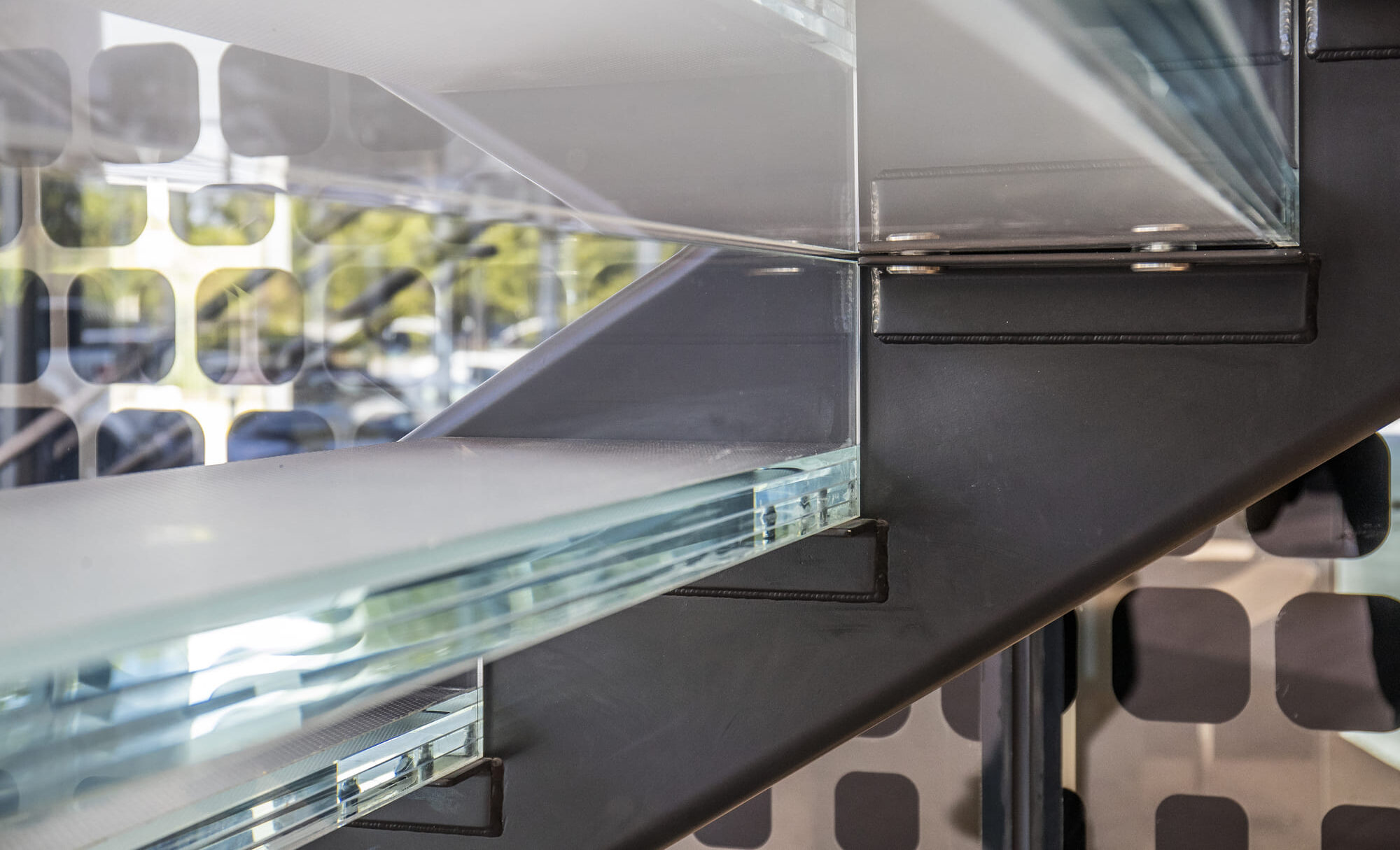

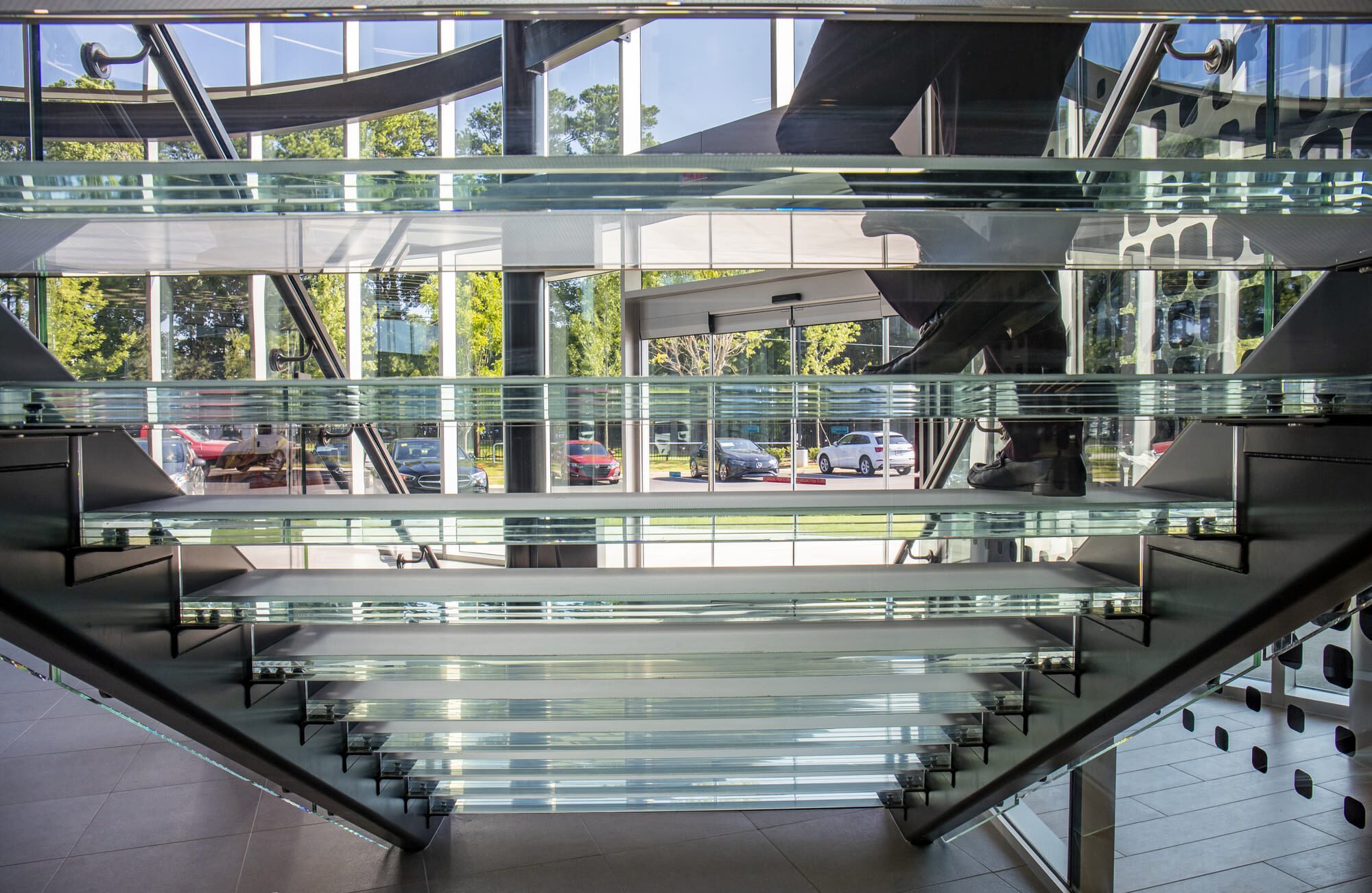

A glass staircase is a load-bearing stair system composed of laminated, tempered glass components, engineered for safety, functionality, and visual clarity. These stairs can be integrated into open-plan layouts, cantilevered for floating appearances, or combined with structural steel framing for large-scale commercial use. Treads are typically made of glass for stairs that includes structural interlayers, polished edges, and embedded fasteners.

Unlike standard staircases, glass stairs invite natural light to flow through a space, eliminating visual barriers and creating architectural openness. The materials are tested to meet stringent performance standards, ensuring they are both secure and stunning.

The Benefits of Using Glass for Stairs

Choosing glass stairs offers both practical and aesthetic advantages. These include:

- Increased Transparency: A glass staircase introduces uninterrupted sightlines and allows natural light to pass through multiple levels.

- Modern Aesthetics: Its minimalist form complements contemporary, industrial, and luxury interior styles.

- Durability: Multi-layer laminated, tempered glass performs exceptionally well in high-traffic environments.

- Long-Term Value: Glass doesn’t warp, rust, or deteriorate the way wood or metal can in certain conditions.

- Low Maintenance: Glass is easy to clean and resistant to many common contaminants.

Floating Glass Staircases: Style Meets Engineering

A floating glass staircase appears weightless while delivering full structural performance. These designs typically use concealed stringers or mount directly into the wall using hidden anchoring systems. Each tread seems to hover in place, giving the staircase a sculptural quality that fits seamlessly into open-concept interiors.

Glass Flooring Systems offers floating stair treads constructed with triple-laminated low-iron glass, mechanical fastening embedded within the glass, and slip-resistant surfaces that meet commercial safety standards. These floating systems are as stable as traditional staircases, but far more visually impactful.

Key Applications for Glass Stairs

Glass staircases are a versatile solution for projects ranging from private homes to large-scale public buildings. Common applications include:

- Residential Spaces: Lofts, mezzanines, basements, or second-floor transitions in modern homes.

- Commercial Offices: Lobbies, central stairwells, or collaborative spaces to inspire and elevate the work environment.

- Retail Showrooms: Transparent stairs that allow visibility between levels without blocking merchandise displays.

- Hospitality Environments: Statement staircases in hotel lobbies, event spaces, or rooftop lounges.

- Cultural Institutions: Museums and galleries benefit from glass stairs that complement curated lighting and open layouts.

Design Considerations for Modern Staircases

Before choosing a glass staircase system, consider these essential factors:

- Span and Support: Determine the structural support method: center stringer, wall-mounted, or side-framed.

- Riser vs. Open Tread: Decide whether you want a riser-free open look or a more traditional style.

- Lighting Integration: Explore LED channeling and diffused perimeter lighting for a contemporary edge.

- Color and Texture: Choose between clear, frosted, or digitally printed options to suit your design palette.

- Load Ratings: Ensure compliance with local code and occupancy load requirements, especially in commercial spaces.

Safety and

Code Compliance

Every glass stairwell must meet safety and performance regulations to ensure durability and code compliance. Requirements typically include:

- Tread depth and riser height

- Guardrails and handrails at specific heights

- Dynamic and static load capacities

- Slip resistance for both wet and dry conditions

- Glass Flooring Systems provides state-specific shop drawings, structural calculations, and third-party testing documentation to help you get through permitting and inspection with confidence.

Structural Support and Framing Options

Support systems are the backbone of any successful glass staircase. GFS offers two high-performance framing systems:

- Aluminum Framing: Lightweight, corrosion-resistant, and ideal for interior or covered environments.

- Structural Steel Framing: Ideal for longer spans and exterior-grade performance. Steel supports more weight and offers extended durability in harsh environments.

In either option, mounting points are reinforced, and connection hardware is engineered for clean finishes and code compliance.

Anti-Slip Textures for Glass Staircases

To ensure that glass for stairs performs safely in real-world use, GFS offers over two dozen anti-slip textures, tested under ANSI A326.3 standards.

Options include:

- NanoDot®: Micro-patterned for subtle traction without clouding the view.

- Seeded Organic®: A natural texture designed to blend safety with artistry.

- Acid-Etched Series: For a frosted, slip-resistant finish with a matte appearance.

All textures are available in both transparent and semi-opaque finishes and are recommended for both interior and exterior installations.

Customization Options: Shapes, Edges, and Finishes

GFS offers complete customization to match your vision:

- Tread Thickness: Adjust based on span and load requirements.

- Custom Shapes: Radius corners, trapezoidal forms, or curved treads.

- Decorative Interlayers: Use colors, printed patterns, or branding elements between glass layers.

- Edge Polishing: All edges are polished post-lamination for clarity and comfort.

- Lighting Channels: Routed into treads or framing for underlit effects.

Every staircase is made to order, and our team works closely with architects and designers to match specifications.

Our Process

Here’s what to expect during a GFS staircase installation:

- Consultation: Review your space, application, and vision.

- Design Development: Engineering drawings, code compliance, and shop submittals.

- Manufacturing: CNC-cut glass, edge polishing, and interlayer lamination.

- Pre-Assembly: Hardware fit checks, pre-drilling, and dry-fit approvals.

- Delivery and Onsite Coordination: Components arrive ready for install with detailed instructions.

- Installation: Either by your crew with our support or by a certified installer.

.png)